Each year tons of non-recycled glass waste ends up in landfills, which adds a possibly unnecessary burden in the waste disposal process. Some argue that a solution to this issue is needed to improve the sustainability of our environment.

In a study published on April 19 in Scientific Reports,Changling Li, a graduate student at University of California, Riverside (UCR)’s Bourns College of Engineering, and his colleagues found a possible solution. They developed a way to use silicon, derived from glass waste, to create anode material for lithium-ion batteries.

Graphite based anodes used in common batteries have a low theoretical capacity of 372 mAh/g. In comparison, silicon has a high theoretical capacity, of 3572 mAh/g, and a low discharge potential. These characteristics make silicon a great candidate for energy storage in batteries.

The researchers claim that batteries with silicon anodes can lead to a 34 percent increase in the total battery capacity compared to batteries with graphite anodes.

However, silicon anodes do carry their own set of risks. They can become unstable when they react with the lithium cathode. This reaction can then cause an unstable pattern of expansion and contraction of the anode.

As a potential solution to this instability, the research team proposed downscaling the silicon to nanoparticles. Silicon nanoparticles have shown to be effective in preventing the anode structure from cracking.

They also plan to coat the silicon with carbon. The carbon coating can act as a buffer when the silicon expands.

Li and his colleagues adopted a method called “magnesiothermic reduction” in combination with sodium chloride to create nanostructured silicon. Sodium chloride is essential during this process because previous research has shown that it can absorb large amounts of heat generated from an exothermic reaction.

It prevents the heat created by the reaction from surpassing silicon’s melting point, thus maintaining silicon’s nanostructure.

This novel process would be cheap and practical for mass production compared to known techniques that require expensive raw material and toxic acids.

Creating a silicon based anode using glass waste involves three procedures.

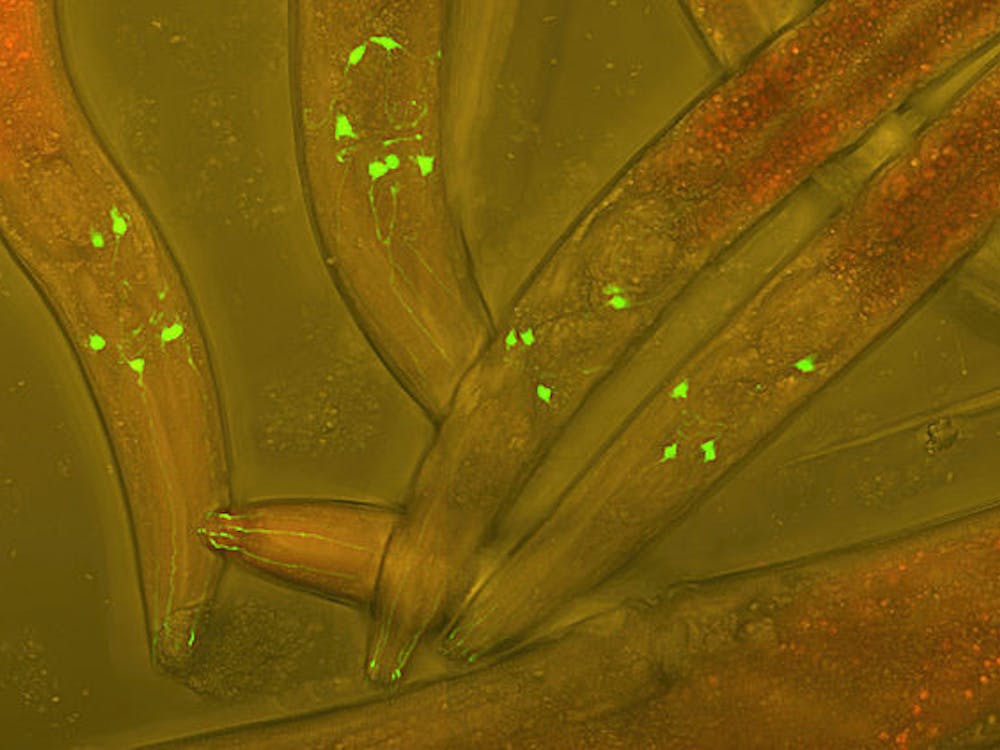

First, the glass must be crushed and grinded so that it is only nanometers in scale. Second, sodium chloride is mixed with the silicon dioxide powder which will later undergo the magnesiothermic reduction process to produce silicon nanoparticles. Finally, the silicon nanoparticles are coated with carbon.

The results of the team’s work show that the glass derived silicon with carbon coating exhibits a capacity of approximately 1420 mAh/g at C/2 after 400 cycles, suggesting good stability and a higher energy density.

Li explained some of the process behind their discovery.

“We started with a waste product that was headed for the landfill and created batteries that stored more energy, charged faster, and were more stable than commercial coin cell batteries,” Li said, according to Science Daily. “Hence, we have very promising candidates for next-generation lithium-ion batteries.”

The research team believes that their battery can be used in electric vehicles or hybrid electric vehicles in the future. Their work demonstrates an environmentally friendly way of converting waste.

According to UCR Today, this study is part of a series of other projects to create a more sustainable environment and is one of the first studies to approach sustainability by creating lithium-ion battery anodes from environmentally friendly materials.