By SYDNEY RIEMER

The Hopkins Digital Media Center (DMC) held a 3-D printing authorization workshop on Thursday. The event was the last in a series of equipment authorization workshops that the DMC holds at the beginning of each semester.

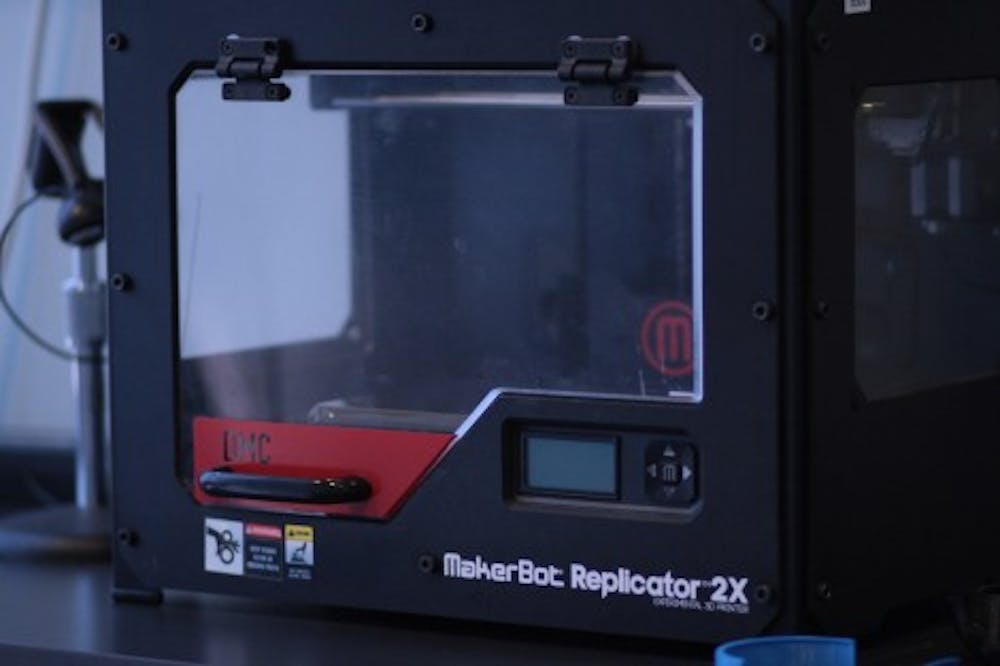

At the 3-D printing workshop students learned the basics of how to use the DMC’s Makerbot Replicator 2x 3-D printer. The DMC has had this printer for three years. Previously they used a rudimentary Makerbot 3-D printer that the DMC student staff built from scratch using a kit. Makerbot is a company based in New York that manufactures 3-D printers.

Instructor Kristen Anchor, one of three multimedia specialists at the DMC, taught the authorization class.

She explained that the DMC’s printer has dual extruders, meaning the printed objects can contain two different colors.

“The public library from where I’m from has a single extrusion 3-D printer, so I’m not used to the dual extrusion they have here,” freshman Seth Tenembaum said.

Anchor explained how to load the filament, the colored wire that is heated to make the desired object and gave a few demonstrations to the class. Students were then allowed to tinker with the printer themselves to practice loading and unloading the filaments.

Another key component to 3-D printing is the modelling software. 3-D printers use 3-D models made on a computer using various types of software. Anchor showed attendees the software the DMC has installed on their computers which are available for student use.

For those who aren’t as well-versed in computer-aided design (CAD), Anchor directed the class to an open source website runis by Makerbot. The website, called Thingiverse, allows you to download the files of other people’s 3-D printed objects so that you can print them yourself.

Some of the students at the event already had experience with CAD. Sophomore Mariah Schrum taught herself SolidWorks, a CAD software, while she was designing race cars in high school.

Although the training to use the printer is free, actual printing is not. This is because the DMC must pay for the filament for the printer.

The prices are $1.50 an hour for the regular filament and $2.50 an hour for dissolvable filament. Dissolvable filament is a special type of filament used for prints with overhangs or movable parts. The amount of time it takes to print an object largely depends on the object’s size. The DMC printer can print objects up to 25 by 16 by 15 cm.

Some students at the workshop were there simply because they were interested in 3-D printing, unsure of how they would actually use the 3-D printer.

“I just thought it looked really cool, and it was quick and now if I ever think of anything to print, I can do it,” sophomore Peter Klinkmueller said.

Other students came with a specific purpose in mind.

“I’m here on behalf of my lab,” Schrum said. “I work for Dr. Taylor in Hackerman Hall in his medical robotics lab. We don’t really know what we’re going to print yet, but in the future it may come in use. We’re probably going to build smaller parts for robots just because we want to test out the parts and see how they work.”

Schrum is not the only student interested in using the printer for research purposes, according to Anchor.

“We worked with an astronomy student who was making models of stars exploding that were really cool. The models that he made are actually attached to papers that he wrote, so that’s pretty neat,” Anchor said. “We also had biology students printing casing for field instruments that they were inventing.”

In the past students have also used the printer for more personal purposes such as phone cases and add-ons to costumes.

Although this is the only formal 3-D printing authorization workshop of the semester, students can still sign up for one-on-one authorizations with a lab coach who is a DMC student staff member.

Lastly, Anchor emphasized the fact that 3-D printing takes a lot of patience and that it can take a lot of time to perfect your prints.

“3-D printing is really fun but you have to be up for trial and error. It’s not really like printing on a laser printer where you type up your paper and hit print and it works almost every time. It’s more like manufacturing or creating art,” she said.